Overview

Our solutions for drywall construction

Sawing and milling machine

GROOVE 90

The GROOVE 90 convinces with its compact design and good portability and impresses with a precise milling pattern and sharp edges. This makes it perfect for daily use on the construction site. The hand-guided milling and sawing machine can be used for a wide range of applications. However, its main applications are routing longitudinal and transverse grooves, V-grooves at 90° and 45° for folding and bending plasterboard, and routing edges for processing aluminum composite panels. The combination with the extraction system allows you to work dust-free, especially when using plasterboard. The use of different guide rails also ensures a high level of precision, allowing you to optimally process panels with a length of over 3,600 mm.

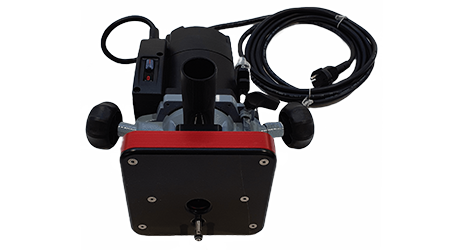

Router VCO

The VCO router was developed for fast and precise routing of openings in timber frame construction. By using special and precisely adjustable cutters (Ø 6 - 12 mm), planking made of OSB, fermacell® and all other common gypsum fiberboards can be processed. The machine is therefore the ideal and flexible companion for the professional implementation of your drywall projects. The strength of the VCO router lies in its application: The large-format boards can be fully mounted on the wooden frame before the cutouts are created using a special end mill with a thrust ring - without measuring, marking or the use of guide rails.

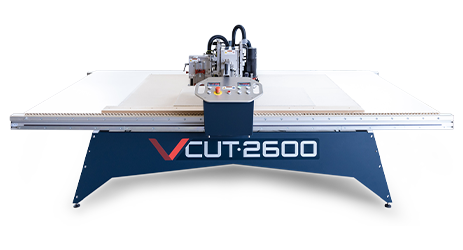

Sawing and milling table VCUT

Our VCUT 2600 and VCUT 4000 sawing and milling tables stand for maximum flexibility in panel processing. They are used for the fast, efficient and professional production of molded parts. With the sawing and routing tables of the VCUT series you have the possibility to flexibly define the machining dimensions and to use panels with a length of up to 3,100 or 4,200 mm. The VCUT machines are robust and designed for the production of molded parts in high volumes. The system guided by x and y axes guarantees a high level of precision. The powerful milling and sawing units also ensure high cutting speed and fast production of folded elements.

CNC milling machine CNC Profi

With our CNC milling machines CNC Profi 1 and CNC Profi 2 we offer two powerful and electronically controlled systems for professional and automated processing of panels of various materials in the size 1,500 x 3,000 mm. The software impresses with its ease of use, wide range of functions and a user-friendly and intuitive interface. Both systems are highly precise, fast as well as economical in the production of molded parts and at the same time massive in their design. The difference lies primarily in the table design. In the CNC Profi 2 version, this is customer-specific and 100% designed to meet your requirements. Made in Germany, of course!

Flexibility is not only important on the construction site, but also in the selection of machines. With our assortment for drywall construction, we ensure that you will also find the right equipment for your area of application.

Machine technology for drywall construction

Our powerful sawing and milling machines are suitable for processing almost all common materials on the drywall and are especially optimized for dust-free work with plasterboard. Our machines are designed for production. From the professional for the professional!

Increase your efficiency and quality with the production of pre-fab drywall shapes. Optimize your time and reduce costs in the production of square or round elements in drywall construction.

Take your craft to a new level with our mobile and hand-guided GROOVE 90, the VCO router optimized for wood frame construction, the VCUT series sawing and routing tables or the CNC milling machines CNC Profi.

Our innovative machine technology is optimally complemented by a carefully selected range of accessories and tools. These include efficient extraction systems, an extensive range for the application of various bonding techniques, and useful tools for drywall construction. You can also benefit from our many years of knowledge in advising you on all aspects of workplace planning and manufacturing methods.

Are you future-oriented and innovative in drywall construction?

Then our products are indispensable for you as a professional!

Your benefits at a glance

- Consistently high quality

- Perfect edges and high precision

- Low dust load

- Fast on-site production

- Efficient prefabrication

- Flexible and without waiting time

In order to achieve the highest level of satisfaction with our products, we will be happy to advise you on everything from machine selection, workplace design and installation to regular maintenance.

Therefore, please feel free to contact us with any questions at any time. We will advise you on the selection of machines, let you test the equipment or organize training courses for your employees. We look forward to your inquiry.