Wide range of design options

Series production of drywall shapes

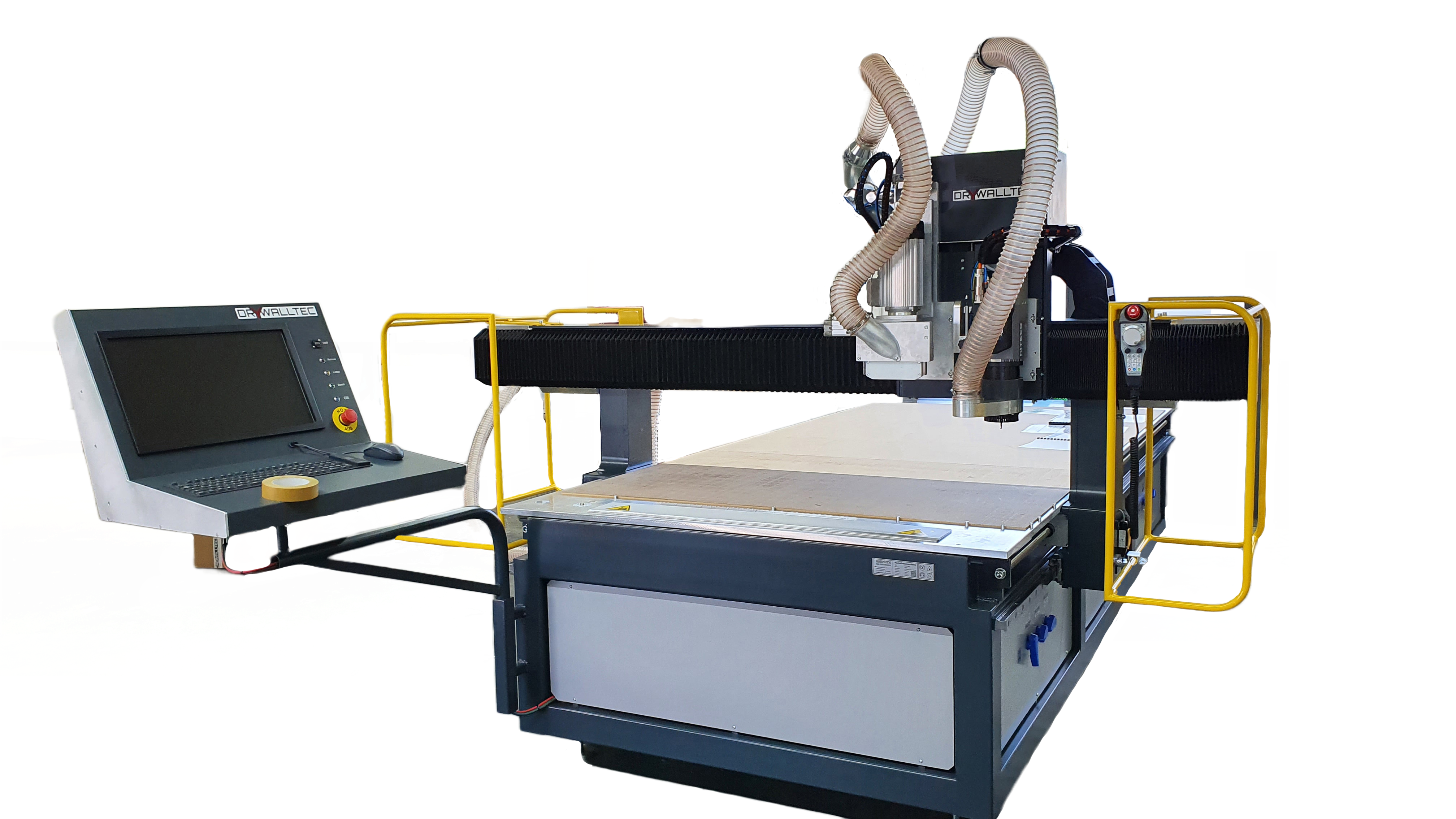

With our CNC milling machines of the CNC Profi series, we offer powerful systems for sawing and milling panels of various materials. The serial production of moldings preformed parts in the size of 1,500 x 3,000 mm panels is made efficient, fast and easy by our systems - so you can combine perfection with a wide range of design options for your drywall projects.

The machines are equipped with rack and pinion drives or with recirculating ball screws including dirt deflectors and taper roller suspension. A stable steel frame construction and a low-vibration portal ensure the best results.

With our CNC milling systems you have all possibilities of design and at the same time series production par excellence at your disposal.

The machines are designed for daily and effective production. A tool changer with up to 10 different milling tools offers you a wide range of machining possibilities.

Especially the sawing function on our CNC machines is extremely profitable for an efficient processing of panel materials. Next to the milling spindle there is a sawing unit that can be swiveled by 90°, allowing panels to be sawn quickly. The swivel mechanism allows sawing in both axes.

Machining of almost all panel materials, dry or with minimal lubrication, is possible. Whether wood-based, aluminum, plastic, insulation, plasterboard, gypsum fiber or cement-bonded boards: the difference lies mainly in the selection of tools and machine parameters.

Besides the CNC milling machine CNC Profi 1 we offer the CNC Profi 2. Both systems are highly precise as well as fast in the production of drywall shapes and at the same time massive in their construction. The difference lies primarily in the table construction: this is made entirely of steel in the CNC Profi 2 version. In addition, the CNC Profi 2 is supplied exclusively with rack and pinion drives, which allow higher travel speeds. The CNC Profi 2 is customized and designed 100% according to your needs.

Both machines have a space-saving design. The control electronics are located in a steel cabinet built directly into the machine - thus no external control box is necessary. Besides the vacuum pump, which supplies the vacuum table (a "checkerboard" pattern milled in 15 mm thick aluminum), only the suction system is located next to the machine. This space-saving concept allows optimum molded part production - even where space is limited.

DRYWALLTEC CNC milling machines

Intuitive usability

Both CNC milling systems are characterized by the simple and intuitive operability of the software: this is unique. Together with our CNC and software partners, we have succeeded in developing a machine and CNC software that convinces beginners as well as professionals.

The numerous presetting options and the clearly structured design of the software make it possible for you to get started immediately with the production of drywall shapes. The well-designed user interface and the wizard guide you step by step through the software - and make it easy for you to get started.