YES Machinery – New distribution partnership in the GCC region

3. January 2024

NEW: GIPS HÄXLER – the powerful drywall shredder

22. July 2025

YES Machinery – New distribution partnership in the GCC region

3. January 2024

NEW: GIPS HÄXLER – the powerful drywall shredder

22. July 2025Vacuum Lifters for Sheet Materials: The Optimal Solution for Loading Milling Machines

Modern manufacturing processes demand innovative solutions to ensure efficiency, precision, and safety. In this context, vacuum lifters for sheet materials are an invaluable technology when it comes to loading materials such as Fermacell, gypsum boards, wood, or plastic onto milling machines. All our vacuum lifters offer a lifting capacity starting at 100 kg. Heavier sheet materials are equipped with stronger suction cups.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe Advantages of VLIFT Vacuum Lifters

Precision and Repeatability

Using vacuum lifters for handling sheet materials enables outstanding precision and repeatability. The suction power can be adjusted precisely to meet the specific requirements of the material, allowing even thin or delicate sheets to be safely and evenly transported to the milling machine—just as reliably as heavy or glued panels. The result: precisely machined workpieces with minimal scrap.

Increased Efficiency

Handling heavy sheet materials can be time-consuming and physically demanding. Vacuum lifters support this process and significantly reduce the strain on your employees. The outcome: higher productivity and a healthier work environment.

Flexibility

Vacuum lifters are extremely versatile and can be configured for various types and sizes of sheet materials.

Thanks to this flexibility, your milling machine can be used for a wide range of projects. Different suction cup shapes and surface grippers allow you to pick up single strips or entire sheets with ease.

Safety

Workplace safety is a top priority. Vacuum lifters significantly reduce the risk of injury by eliminating the need for manual handling of heavy sheet materials. This not only helps prevent accidents and injuries, but also provides clear economic benefits.

Reduced Operating Costs

Vacuum lifters help lower labor costs and material waste while also being energy efficient. They only consume energy when actively lifting materials, which contributes to lower operating costs.

The vacuum lifters can be mounted on various crane systems:

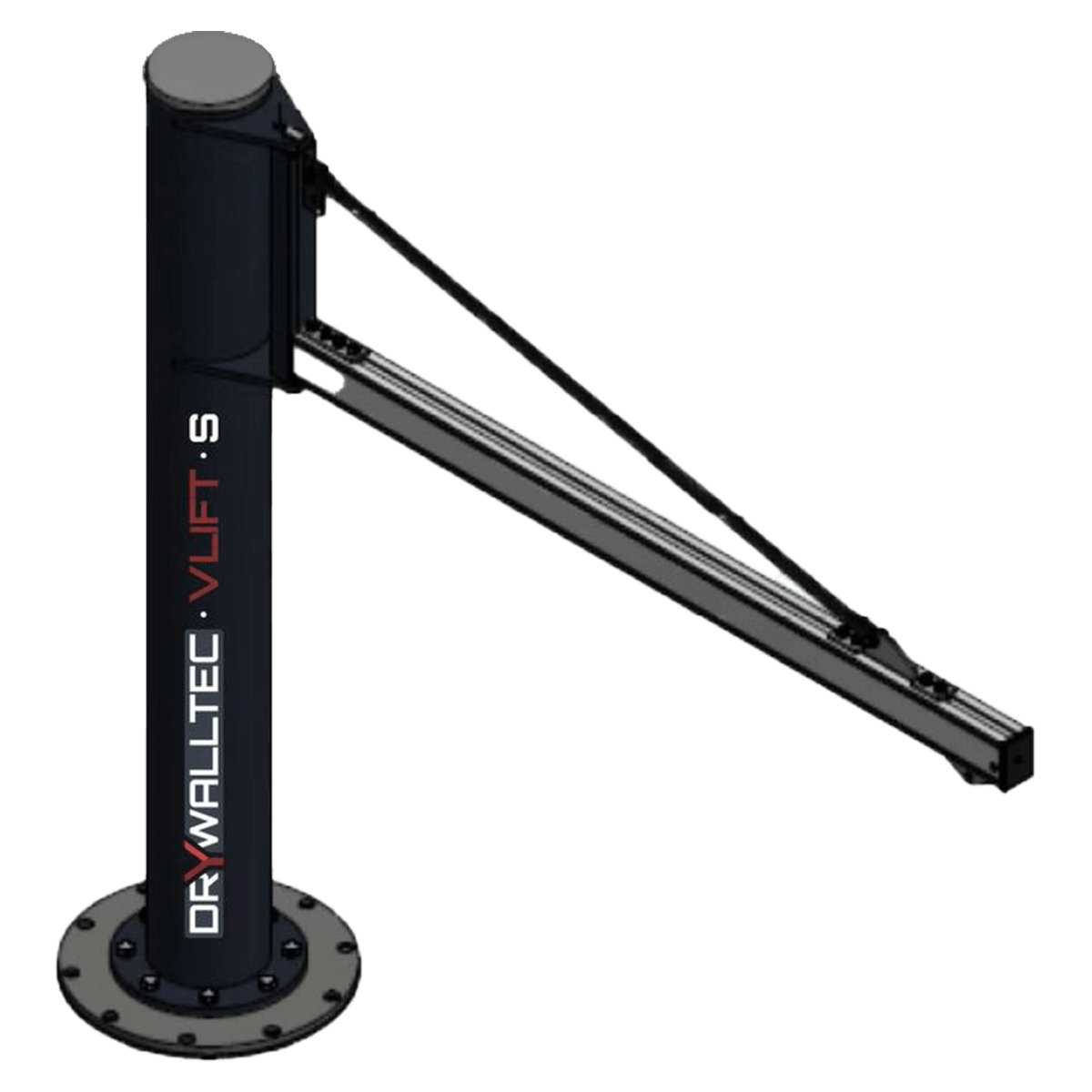

Pillar Jib Crane

A pillar jib crane is a highly flexible and space-saving solution for transporting sheet materials. With jib arms up to 6 meters long and a 270° swivel range, it allows heavy loads to be lifted and precisely maneuvered in multiple directions.

Mobile Base Plate Pillar Crane

A flexible option with a mobile base plate allows use at multiple workstations. It can be moved by forklift or on wheels, eliminating the need for floor anchoring. The swivel range is the same as that of a standard pillar jib crane.

Overhead Crane System

An overhead crane combined with a vacuum lifter provides an almost effortless way to move heavy sheet materials across a large working area. With no obstructing columns or floor elements, everything is suspended from the ceiling, allowing maximum freedom of movement.

Wall-Mounted Jib Crane

A swiveling jib or articulated jib arm mounted on a wall or existing column. It operates similarly to a pillar jib crane, but the jib arm is fixed to the wall instead of a standalone pillar.