Thanks to this innovative technology, efficiently producing pre-fabricated drywall shapes on the construction site as well as in the factory is a breeze.

The continuous development of mechanical engineering has made the VCUT 2600 and VCUT 4000 what they are today:

The benchmark for pre-formed plasterboard and drywall shapes.

The VCUT 2600 and VCUT 4000 are stationary milling and sawing tables with modular units for milling and sawing panel materials, mainly for plasterboard and other finishing panel materials such as fermacell® or OSB.

The VCUT machines offer a multitude of advantages that make your work as a user easier. Two different table lengths offer maximum flexibility in the production of pre-fabricated drywall shapes.

With the VCUT 2600, sheets of up to 3 meters can be sawn or milled. The VCUT 4000 offers an even longer working area allowing 2 x 2 meter sheets to be processed simultaneously one after the other.

Thanks to interchangeable units, the VCUT series offers an incredible variety of machining options including milling, sawing and duplicating. The units are designed for performance and continuous operation and provide the highest technical standard.

Do you want to produce drywall profiles professionally?

We have the machines and the experience!

VCUT

Advantages for you

The technical advancement compared to other panel processing machines is reflected in the solid construction.

Our focus is on production. True to the motto: "Made for Production".

- Save over 80 % of time in the production of edgebandings

- Perfect edges without filling – ready to paint

- Fast and flexible production of pre-fabricated drywall shapes in large or small quantities

- Value creation stays in the company

- Optimized material consumption – scraps can be processed into pre-fabricated drywall shapes

- Very fast and inexpensive production of standard pre-fabricated drywall shapes (e.g. L-brackets, U-shells, etc.)

- Serial cuts of gypsum beams, wooden beams, bathroom cut-outs

- Cutting and milling of reveal panels

- Production of light coves, sliding ceiling connections, niches and boxes

- Fire protection cuts of up to 60 mm thick sheets (e.g. Promat or similar)

Dimensions (installed with portal)

- Length: 3.500 mm

- Width: 1.950 mm

- Height: 1.200 mm (approx.)

Weight

- Table: 150 kg

- Portal: 75 kg

Processing dimensions (double sided)

- Lengt: 2.600 mm

- Width: 1.300 mm

- Height: 80 mm

Cutting depth (saw) 65 mm

Milling up to 150°

Processing dimensions (one sided)

- Length: 3.100 mm

- Width: 1.300 mm

- Height: 80 mm

Sheet format (max.)

- 1.300 x 3.100 mm

Electrical requirement

- 120/230 V – 50/60 Hz – 16 A

Dimensions (installed with portal)

- Length: 4.950 mm

- Width: 1.950 mm

- Height: 1.200 mm (approx.)

Weight

- Table: 180 kg

- Portal: 75 kg

Processing dimensions (double sided)

- Lengt: 4.100 mm

- Width: 1.300 mm

- Height: 80 mm

Cutting depth (saw) 65 mm

Milling up to 150°

Processing dimensions (one sided)

- Length: 4.600 mm

- Width: 1.300 mm

- Height: 80 mm

Sheet format (max.)

- 1.300 x 4.200 mm

Electrical requirement

- 120/230 V – 50/60 Hz – 16 A

- Maximum flexibility in production

- Milling of pre-fabricated drywall shapes at almost any angle (30 ° to 150 °)

- Rational production of slotted sheets

- Circle cut-outs with compass device

- Easy copy milling and duplicating of shapes such as toilet cut-outs

- Electric and automatic lifting and lowering of the units

- Robust mechanical switching mechanism of extraction to the respective unit

- Quickstop mechanism on y-axis for faster calibration

- Dryline bearings ensure durable operation under the toughest conditions

- Powerful electromagnetic clamping for x and y axes

- Digital and accurate measuring system on both axes with multi-stop function

- Convenient laser adjustment on the units

- Optimum dust extraction during the production process

Units for the VCUT series

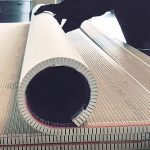

Standard milling unit

- Standard powerful and robust milling motors, specially designed for the stresses of milling gypsum and other board materials

- 1.8 kW standard milling machine with convenient milling depth adjustment

- Robust and warp-resistant construction

- Extra large hose connection guarantees dust-free milling

- Fixed lasers with cross display show the center of the cutter and simplify positioning and measuring

- Supplied with collets in 8 mm and 12 mm for full flexibility

- Boreholes for compasses in the sliding plate for creating circular cut-outs

- Optimized for milling reveal panels with groove cutter

Industrial milling unit

- Extra Power! Very powerful and robust milling motor, especially for the loads when milling hard gypsum board materials and products containing cement

- 2.6 kW power milling machine with convenient milling depth adjustment

- Robust and warp-resistant construction

- Extra large hose connection guarantees dust-free milling

- Fixed lasers with cross display show the center of the cutter and simplify positioning and measuring

- Supplied with collets in 8 mm and 12 mm for full flexibility

- For use with V-cutters up to an angle of 150°

- Optimized for milling reveal panels with groove cutter

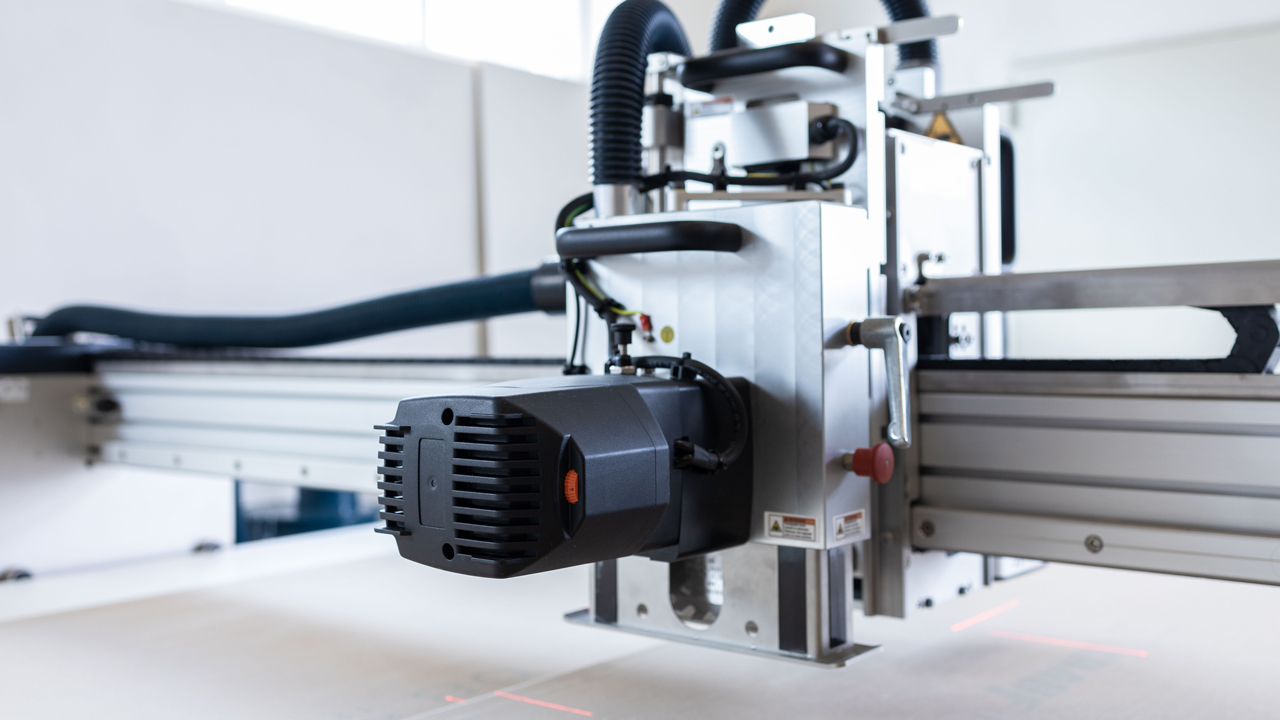

Universal sawing unit

- 2.3 kW powerful saw motor with extra power reserve for series production

- Cutting depth of 65 mm

- 1 unit for all applications:

- Single cut

- Multi-saw with 5 saw blades

- V-groove saws

- Rectangular groove saws - Innovative swivelling technology of the sawing unit for x and y axes

- Convenient laser adjustment

- Multi-saw package for curves, columns and arches